Views: 0 Author: Site Editor Publish Time: 2025-03-28 Origin: Site

With the advancement of science and technology and increasingly fierce market competition, product lifecycles are accelerating. Shortening the design and prototyping cycle of new products while reducing development costs has become an urgent challenge for every manufacturer.

Over the past 30 years, computer technology has become a powerful tool across various fields. While computer-aided design (CAD) significantly improves design efficiency and quality,prototyping cannot address all the challenges in the manufacturing process. Between product design completion and mass production, prototype samples often need to be fabricated to validate and refine the design early on—a time-consuming and labor-intensive task that has become a major bottleneck.

Rapid prototyping technology, which generates three-dimensional objects directly from computer models, has emerged in response to the growing demands of modern design and manufacturing. This interdisciplinary technology integrates mechanical engineering, automatic control, laser technology, computer science, and materials science. In recent years, it has been widely applied in industrial design, manufacturing, architecture, art, medicine, aviation, aerospace, archaeology, and film production with remarkable success.In the future, intelligent mold rapid prototyping technology combined with artificial intelligence optimization and digital twin monitoring will further promote the transformation of the manufacturing industry towards

digitalization and personalization.

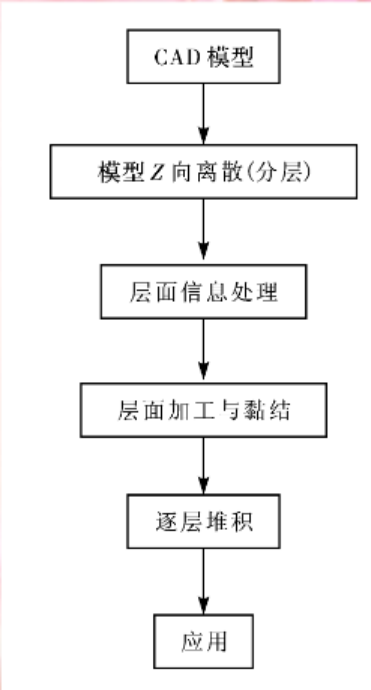

There are various specific process methods for rapid prototyping technology, but their fundamental principles remain the same. The core concept is based on material addition manufacturing. The goal is to quickly (compared to machining) transform a 3D CAD model into a physical three-dimensional prototype composed of actual materials. The process can be divided into two stages: discretization and layering.

First, a 3D CAD model is obtained either through a CAD modeling system or by measuring the dimensions of a physical object and converting them into a digital model. The model data is then processed and discretized into planar "layers" along a specific axis. Subsequently, a dedicated CA system (prototyping machine) processes and deposits the forming material layer by layer until the prototype is completed. The process is illustrated in the following diagram.

(Note: Since you mentioned "the process is shown in the figure below," I included a placeholder for the diagram reference. If you have a specific figure label, you can adjust accordingly.)

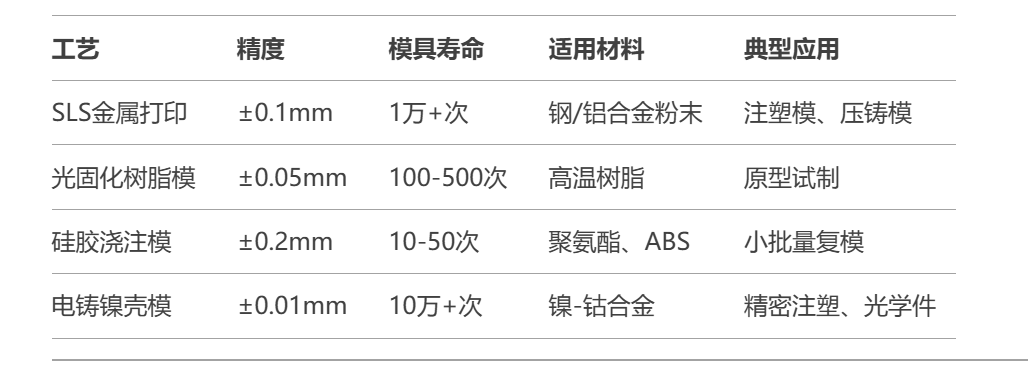

Rapid Tooling (RT) is a combination of Rapid Prototyping (RP) and mold manufacturing technology, aims to shorten the mold development cycle, reduce costs and enhance flexibility.The rapid prototyping technology of molds greatly shortens the mold development cycle, and is especially suitable for small batches, complex structures, and rapid trial production scenarios.

Mold rapid prototyping technology reconstructs the traditional mold process through digital means, and has significant advantages in the field of agile manufacturing and personalized customization.Mold rapid prototyping technology, as the core innovation means of modern manufacturing industry, is reshaping the traditional mold development process with its characteristics of high speed, low cost and high flexibility. This technology can complete the mold manufacturing that takes weeks to achieve by traditional processes in hours to days through direct rapid mold making (such as metal 3D printing) or indirect rapid mold making (such as silicone mold turning), especially suitable for small batch trial production, complex conformal cooling molds and rapid product iteration scenarios. With the development of high-performance metal powder and mixed manufacturing technologies, mold rapid prototyping technology is breaking through the limitations of life and precision, and realizing the agile manufacturing model of "design is production" in the fields of automotive, electronics, and medical care. In the future, the intelligent mold rapid prototyping manufacturing technology combined with artificial intelligence optimization and digital twin monitoring will further promote the transformation of the manufacturing industry in the direction of digitalization and personalization.